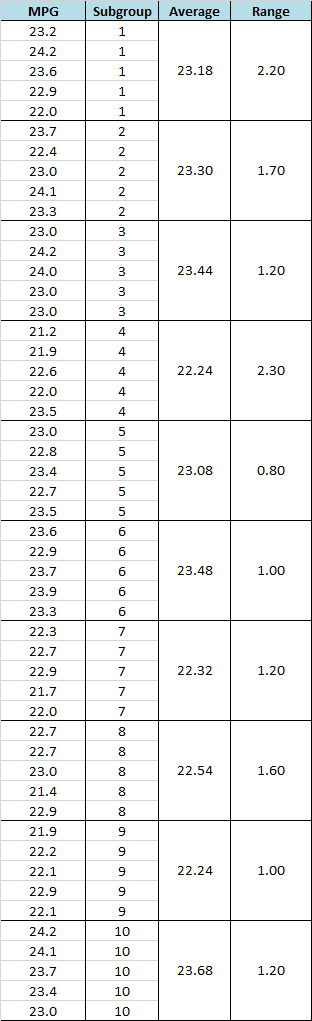

You then plot the Xbar values on the Xbar chart and the range values on the R chart. X-bar and R and X-bar and S Charts Statistical Thinking for Industrial Problem Solving, presented by JMP SAS 4.8 (68 ratings) 6.4K Students Enrolled Enroll for Free This Course Video Transcript Statistical Thinking for Industrial Problem Solving is an applied statistics course for scientists and engineers offered by JMP, a division of SAS. Note that we have an estimate for the population parameter mu anytime you see a hat over the population parameter, it means that its an unbiased estimate. The first step is to estimate the process average. Once mastered, it provides data to leaders on changes they should make as well as measuring the success of changes put into place. The subgroup averages (Xbar) and range (R) have been included in the table as well. Our learning objective is to assess capability from an Xbar and R chart for data that is normally distributed. Note: D3, D4, and A2 were all obtained from the Control Chart Constants Table for a sample size of n = 3.Īn x-bar R chart is one of many tools in Lean and Six Sigma that accurately measure an organization’s performance. The subgroup sample size used in the following example is three. The following is an example of how control limits are computed for an x-bar and R chart. If you only have the summary data (averages of five values), you can chart the XBar data using xbar.one qcc chart type (aka 'individual chart') as depicted in the answer above. For the first chart on a process, collect at least 20-25 sample groups to ensure that an adequate measure of process variation has been taken You would need the individual values to correctly create an XBar-R chart with qcc or other stats packages. Traditionally, it has been suggested that you use the X -R chart with subgroup sizes of 9 or less you use the X -s chart with subgroup sizes larger than 9.The data should be collected in a random and consecutive manner X Bar R charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients blood.The sample size (sub-group) must be at least two and should not be more than about 10-12.Some notes to keep in mind when creating an x-bar R chart include: They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. They measure performance on any type of process, from all the steps in a manufacturing process to determining the time customers must wait in line at a pharmacy.Īn x-bar R chart can find the process mean (x-bar) and process range (R) over time. X-Bar R charts are commonly used to examine the stability of a process over time.

0 kommentar(er)

0 kommentar(er)